Digitalization for a transition to positive impact farming in France

Local context / Issue:

The cooperative TERRENA supports all types of agriculture, all farm models and all production methods. The board of the coop decided in 2008 to put agroecology in the focus. The objectives are: i) maintain high yield production and ii) reduce the use of non-renewable inputs of its farmer members. Digitalisation is already considered by Terrena teams as a way to enable agroecology.

The question related to the showcase is:

“How to make a better usage of the tools (incl. tools implemented by the cooperative) to promote agro-ecology farming and “positive impact farming”?

Showcase Outlook

“Be realistic, demand the impossible”. The old French nonconformist spirit still lingers. Especially in the always-pressured agrifood sector. And Terrena, one of the top cooperatives in France, knows it very well.

In 2012, Terrena was a pioneer in creating and investing in innovative services to respond to the many and complex challenges agriculture and farming were -and still are- facing. Through its subsidiary, Terrena Innovation, the cooperative pushes forward to help farmers modernise and be more competitive. A mission perfectly aligned with the program France 2030, through which the French government is fast-tracking “the third agricultural and food revolution based on three pillars: digital technology, robotics and genetics”.

And how to mobilise digital resources for the better is crucial to adding social and economic value to a sector that is the country’s leading industrial sector and Europe’s leading agricultural power.

As other showcases struggle with the digital divide among older farmers and advisors, in the one with Terrena’s farmers, digital tools are recognised as an enormous beneficial to support their work. However, participants at the local workshop called for more pragmatic, simple and integrated solutions as they see current tools as too complex and time-consuming. Bureaucracy and uploading data many times to multiple platforms are a problem to be solved.

Cost and implementation, data sharing outside the cooperative and especially with the food industry, privacy, and integration with existing systems are also relevant questions to be addressed.

And, again, the transition to agroecology through technology arises doubts and concerns. As in other countries, farmers believe digital tools should serve them, not the other way around.

Resilient, sustainable, competitive, innovative, healthy and traceable agriculture as a commitment. And agroecology as a means as an end. It seems that there is a lot to do. But in France it is just a matter of realism: it is about asking the impossible.

Showcase at a glance

Showcase representative name: VEGEPOLYS VALLEY with its member TERRENA.

Challenge of the showcase: “Digitalisation for a transition to positive impact farming”

Type of production: Arable crops, seed production (maize) and animal breeders (dairy cows).

Type of agroecology: Conventional to integrated farming.

Participants: 15 participants: 12 farmers, with 3 of their advisors all from 2 of the 15 local areas of the TERRENA cooperative.

Showcase representative: Bertrand Pinel – bpinel(at)terrena.fr; Emeline Defossez –emeline.defossez(at)vegepolys-valley.eu

Location: Near Angers, France.

Website: https://www.terrena.fr/

Testimonials

- Podcast with the showcase ambassador :

- Farmer’s interviews:

https://www.path2dea.eu/service/news/voices-from-the-field-interview-to-david-french-farmer.html

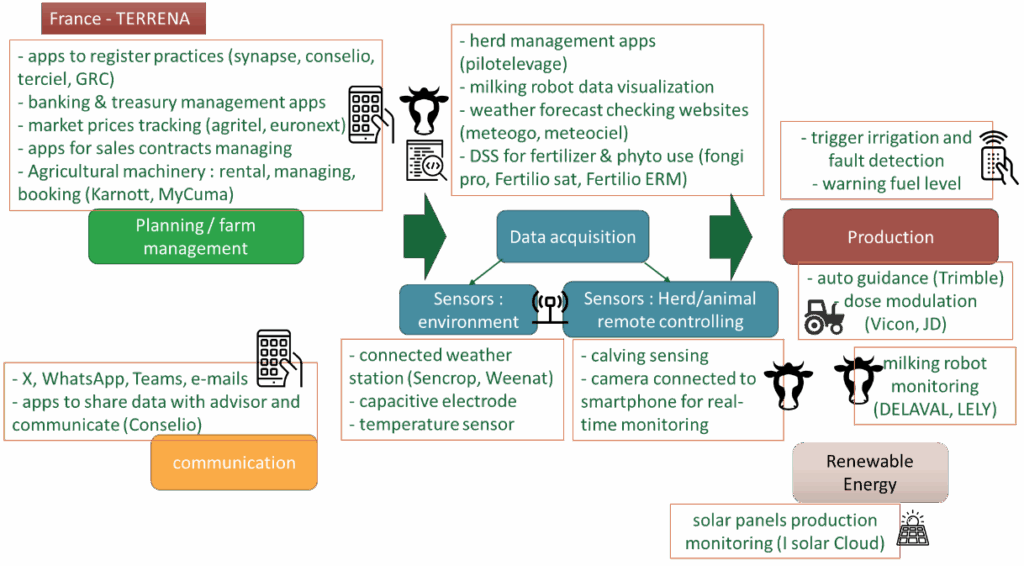

Mapping of digital tools used in TERRENA’s showcase

A diversity of tools is used in the showcase, covering most of the range of existing digital technologies and supporting a diversity of operations on the farm. The picture illustrates the main tools for the main processes on the farm. More details about the tools are available in the Digital Tools section (link)

Usability/applicability of DTs: Main drivers, barriers, risks and trends

Drivers: #simplicity of the tool #working comfort #interoperabilityFor DSS, the economic driver was not a top priority, it was rather the global performance and precision of decision provided.

Attendees declare that they would use more FMIs (like Consélio by TERRENA) as these kinds of tools were more intuitive/easier to use and if they allow quick data entering (double entry…). They would also use guidance, camera because they allow remote access, providing a working comfort.

Reason of choice for sensors is mainly the price (discount opportunity?), number of options, interoperability with other tools and reputation of the provider. For communication tools, a driver is speed/facilitation of exchange, as much from advisor to farmer as between advisors for expertise sharing.

Another driver for any kind of tool is the innovation wish: « being proud to be among the first using these tools » & opportunity to reduce inputs (less money waste & better environmental impact, “clean job”).

Barriers: #ROI & cost #interoperability/compatibility #poor connectivityThe high cost of investment is a barrier, especially for small farm sizes, then trouble with tool compatibility (app and tractor console) that demands training, also lack of connectivity.

Risks: #dependency #social disconnectionDependence on firms and tools (linked with loss of common sense, lack of anticipation, panicking when it no longer works…). Time wasting. Lack of disconnection: possibility for a too thin separation between professional and personal life (“We check the milking data first thing in the morning”). Loss of social connection. Data loss. Theft of costly equipment.

Looking to the future/trends: #weather forecast #automation & robotics #precise spraying Reliable weather forecast applications: many tools exist but they are sometimes not comparable and give different results, it seems like reliable information can be found for the next 10 to 15 days, but it would be nice to predict further dates. Robotics: autonomous & smart tractors to replace the driver and detect and repair field anomalies without human surveillance (ex: debug when tractor gets stuck). Apps that allow data transfer between different tools & different operators (search of a higher interoperability). App connected with tools: e.g. for spraying: with simple scan of the product, and thanks to GPS location it automatically registers in a dedicated app, an operation with the scanned product, on the precise location of the tractor. Some companies are already developing some solutions, like Aptimiz visited by the Path2DEA consortium at SIVAL trade fair 2024 – France. The showcase is particularly interested in precision farming solutions with soil resistivity maps to adapt quantity of inputs (seeds and PK fertilizers) and satellite images to manage N fertilization on wheat and oilseed rape. Indeed, several technological bricks exist already (sensors, algorithms, smart tractors and smart implements…) but some links seem to be missing between these bricks, so that unfortunately this digitalised farming can’t spread as easily as wanted to farmers. We are thinking in particular of the crucial step of transferring the task-maps received on the farmer’s computer, to the electronic tractor consoles.

The added value of the used digital tools and technologies

When grouped according to specific management activities, digital tools and technologies become key enablers of the agroecological transition. Their combined use supports more resilient and sustainable farming practices. Explore how digital tools and technologies enhance this showcase management—step through the timeline of its core activities.

More details about the tools are available in the Digital Tools section (link).

Wheat crop production / positive impact farming

What do farmers from this showcase expect as improvement or new function for digital tools to enhance their transition to more agroecological practices?

At farm level, recommendations regarding improving tools that are expressed are: a better tool user friendliness, better interoperability with other tools (to avoid double registration, to avoid having to extract and download data to give feedback, use the advice), better robustness, better connectivity, integration… they can also think of interested products that are not implemented due to high cost. They sometimes feel that digitalisation is a burden (a lot of data requested, registration is time consuming). They consider themselves far from processing and distribution process.

At the supply chain level, it was expressed that data registering/traceability/data visualizing platform don’t communicate enough at the end of the chain, after the cooperative, although it communicates well from farmer to adviser to cooperative (consélio tool). The end of chain needs to know which practices were implemented in the farm to check if the production system follows specifications. Farmers express that due to bad communication between tools, they need second registering, they need also sometimes to extract/download data to give feedback. They may need to be checked in person although the check could be made mostly by having a look at the software. On top of this, so much info is asked that everything can’t be registered, some info must be written on paper. The specifications are too detailed according to farmers, unnecessarily. The importance of giving consent for sharing data to outside the farm/Cooperative (to the food industry) is expressed by farmers too.

More details on the gaps found in the 6 showcases can be explored in the Gap Analysis section (link).